Overview

A powered roller chain conveyor is a type of conveyor system used for moving material through production lines. Roller chain conveyors utilize a powered continuous chain arrangement, carrying a series of rollers. The automotive industry commonly uses chain conveyor systems to convey car parts through paint plants. These are the most versatile and economical powered conveyor systems. This system is driven by electric motors. Different electric motors as per application are used, for example AC induction motors, AC reversible motors, etc.

Problem Statement

Industries using roller chain conveyors or belt conveyors handle objects of different shape and size. There are events when certain odd shaped products cause locking or jam the conveyor. When this happens damage can occur to both the product moved by the conveyor as well as the conveyor equipment. Stopping the conveyor quickly can reduce costly damage from occurring.

The conveyors are equipped with an electric motor. When an object gets stuck the roller links gets jammed, it blocks the system causing a locked rotor situation. Because of this locked rotor situation, over current occurs and it damages the motor winding. This may lead to unplanned maintenance shutdown of the system.

Hence, it is imperative to monitor over current of the motor and actuate a system which will disconnect motor from supply, avoiding further damage to the system.

Solution

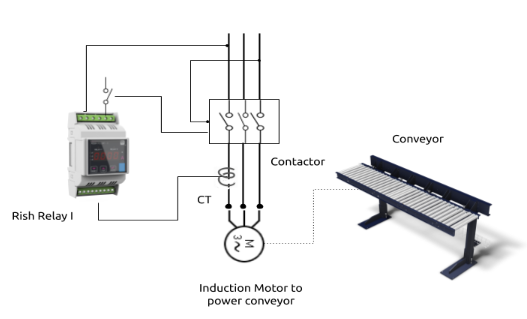

Rishabh’s Digital Current monitoring Relay, Rish Relay – I monitors Over Current along with other parameters effectively. Rish Relay – I offers effective roller chain and conveyor protection. The trip time can be set as low as 0 secs i.e. instant tripping to upto 30 secs resulting into fast actions providing better system protection.

Working

When Overcurrent occurs because of locked rotor condition in motor, Rish Relay – I initiates the change and avoids the locked rotor status which may lead to a damage in the system. Rish Relay – I is capable of monitoring Over current, under current, loss of current or imbalance in current and provides a relay output, which can be set as NC or NO i.e. either an open or close operation.

An LED visual indication provides a diagnostic alert of an alarm condition. A built in time delay for the relay activation is available in order to prevent relay chattering around the set point during under current monitoring.

Benefits

- In addition to tripping, customer can read tripping and resetting values on the display

- IDMT characteristics can be implemented to achieve quick operation during high current inrush

- Trip or Buzzer mode for efficient alarming

- Capable of storing last 15 faults for easy recovery and fault anticipation

Features

- True RMS Measurement

- Trip relay cum DPM with Class 0.5

- 4 digit 7 segment LED display

- 4 different parameters on site selection

- Stores last 15 faults

- Configuration via USB-based PRKAB

- Dual color LED for fault indication

- Detection of fault with display of parameter value