The Problem

For electrical transmission and distribution system, transformers are the most crucial assets. Failures of any sorts in transformers can lead to power outages, personal and environmental hazards and expensive rerouting or purchase of power from other suppliers. Transformer in service interruptions and failures usually result from dielectric breakdown, winding distortion caused by short-circuiting withstand, winding and magnetic circuit hot spot, electrical disturbances, deterioration of insulation, lighting, inadequate maintenance, loose connections, overloading, failure of accessories such as OLTCs, bushings, etc. The failure rate of transformers in India is in the order of 12 to 15% as against less than 1% in developed countries.

Condition monitoring of transformers is the process of data acquisition and data processing of various parameters so as to predict and prevent the transformer failure. This is done by observing the deviation of the transformer parameters from their expected values.

To avoid the transformer downtime as well as asset exhaustion we recommends the following solution:

The Solution

Condition monitoring is advantageous for transformer health assessment in numerous ways as it determines insights regarding the causes & effects of the transformer deterioration.

Monitoring of transformer on online basis is a much efficient tool as it is beneficial for an increase in performance, reduce failure risks and it cuts maintenance costs. The data is taken from primary and secondary windings and the evolving trends of parameters such as temperature, loss, efficiency & loading etc.

- Monitor Efficiency trends- A client can see the loss in efficiency.

- Monitor electrical parameters- A client will be able to see parameters like efficiency, power factor, unbalance, neutral current, surface temperature etc. as well as see their threshold values and the actual transformer values.

- Provide suggestions- To improve the parameters like power factor, unbalance, neutral current, surface temperature etc. which in turn will improve efficiency, the transformer condition monitoring provides suggestions for the same.

- Provide what-if analysis for improvement in efficiency- Basically predicting the improvement in efficiency/reduction in the loss by improving certain electrical parameters, via models fit to the data set.

- Insight Tests trend and Health status

- Key Industry Benchmarks- Key Industry Benchmarks for each test and comparison with personal best

- Recommendation- Recommendation for improvement and ROI for the return to personal best.

- Projected/Predicted efficiency- Predicted efficiency over the next 3 months.

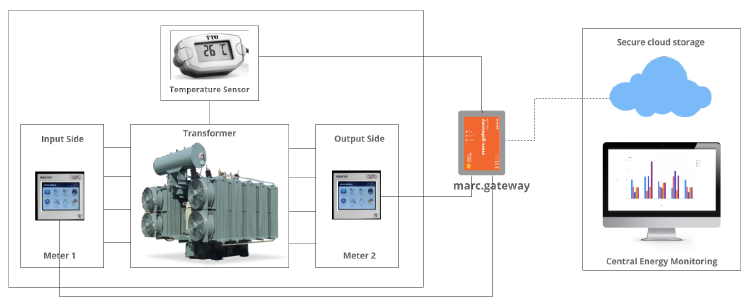

The following equipment is proposed together with the schematic:

Transformer condition monitoring doesn’t have ROI by itself, but the actions performed on the insights provided by it can have ROI. The analytics is so effective tool, so its ROI will be less than a year. The ROI is event/activity based therefore it can be of limited guaranteed where it provides the saving only if a customer takes action upon recommendations.

ROI can be calculated in different ways:

- Increase in Efficiency =(Cost /(Gain In Efficiency x Total Load x Operating hrs))

- Reduction in Breakdown

- Reduction in Production loss with proper planning

The Benefits

- Safe, reliable, easy to use and cost effective transformer monitoring system.

- Through remote access, the asset owner can evaluate the status of the equipment without dispatching an engineer to the site, saving both valuable time and resources. Compared to traditional transformer diagnostic methods, which are performed onsite with the transformer de-energized, it gives the asset owner access to real-time condition monitoring, even from remote locations.

- When changes in operating conditions are detected, the operator is notified immediately with probable cause of change and remedy to act upon.

- Since monitoring detects condition changes in real-time – versus periodically with traditional diagnostic methods – the asset owner has time to plan and act before faults occur.