Overview

Multi-meters are in the markets since a long time and have evolved at the stage where it’s use is not only restricted to maintenance work but it can work as reference measurement devices in different calibration and testing labs or during product testing to measure various outputs such as current, voltage, resistance, frequency, duty cycle, digital outputs and other reference parameters. New communication protocols integrated in the multi-meter devices makes the data recording and test report creation a closed-loop automated process hence removing manual error and keeping a low cycle time for the entire process.

Problem Statement

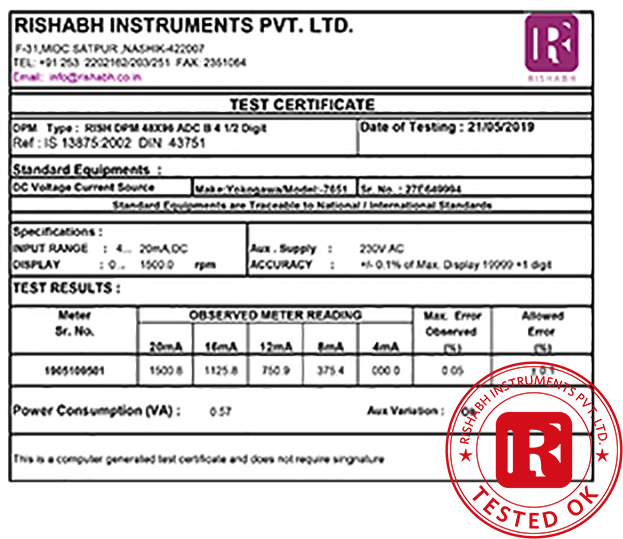

Various measurement results are recorded during product testing on production lines and at labs for testing & calibration purpose and to produce the expected test and calibration reports and guarantee product performance.

Since the required measurement parameters or sample count can be too much in some cases, it can be a nightmare for the product tester or lab technician to note down each and every measurement point and average it without any human error or typographical errors which may lead to incorrect or inappropriate results and can result in added time required to do the already manual work. Multi-meter with communication can be integrated into a PC software or a mobile app to form a closed loop automated testing and report generation program thus solving the above problem.

Solution

A multi-meter can work with plug and play communication ports such as standard USB or Bluetooth communication mode of data transmission. When it is connected to a PC or a mobile app for data processing via a closed loop automated testing program, it can simplify the process for product tester on production lines or lab technicians responsible for testing the reference values.

Rishabh make multi-meters provide such a feature to users and are in use on many shop floors and labs.

The process avoids human errors and reduces time required to record the test value which then flow to the digitally generated reports which are digitally signed. If the process requires, then the values can flow back to the testing program and form a closed loop calibration and testing cycle.

This helps in testing multiple values with respect to the set tolerances hence passing or failing a certain product during production process or simply records the values in a lab ensuring complete traceability for the lab technician by the use of software with the generation of the report in PDF or desired format.

Featured Product

Benefits of Rishabh 60XX series multi-meters

- Data logger & view function (up to 32000 readings)

- Plug and play USB connectivity with PC or Bluetooth connectivity with mobile & PC with Android and iOS app

- 100kHz bandwidth for voltage measurement

- 1kHz low pass filter mode

- NO-GO function

- VAC with 1M impedance

- 4-20mA/0-20mA scale type measurement

- Single fuse for mA & A

- Adjustable square wave output

- Temperature measurement with J, K, Pt100 & Pt1000 sensors

- External power adapter for long hours of measurements

- Selectable clamp ratio for current measurement

- Conductance measurement

- Frequency / time period measurement

- Up to the mark installation category safety with 1000 V CATIII / 600 V CATIV