Overview

Chlor-alkali plants produce chlorine and caustic soda. The most preferred method to produce chlorine and caustic soda is Membrane Cell Process. In this process, electrolysis takes place using metal anodes and metal cathodes partitioned by cat-ion exchange membranes. The electrolysis process is a direct current (DC) process, due to the nature of element connection and chemical reactions the process works at high direct current and low voltage. In order to deliver a high power stable DC power for this process a transformer rectifier is required.

Problem Statement

The transformer rectifier arrangement consists of :

- Rectifier transformer(OFWF, OFAF, ONAN)

- Thyristor Rectifier(6 pulse, 12 pulse, 18 pulse, 24 pulse etc.), forced water cooling or air cooling

- Heat Exchanger(Deionized water)for rectifier

- Copper bus bars

- High current measurement meter

- DC disconnector

- High voltage switchgear

- Harmonic filter

- Power factor compensation capacitor bank

In order to ensure the proper functioning of the arrangement it is essential to monitor the high direct current passing through. As the current in the circuits is of high amperes i.e. upto 50kA – it becomes difficult to monitor it directly using a meter. Thus, an element capable of stepping down the high direct current is required.

Solution

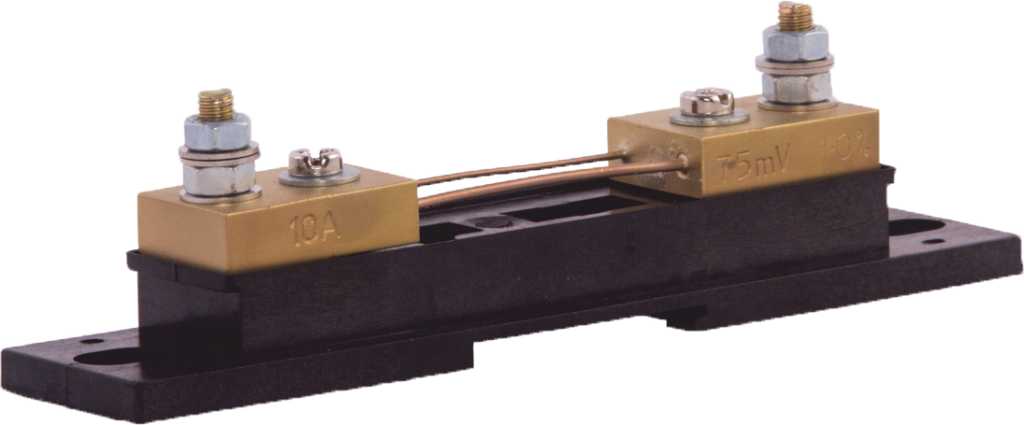

- It is essential to use a resistor or shunt which can measure high currents of up to 50kA

- Here an external shunt is used to step down the high current to mV (50mV, 75mV, 100 mV – as per requirement)

- Therefore Rishabh shunts are ideal for such conditions that are reliable and can carry high amount of direct current without much effect on its mV value even if the temperature rises

- The shunt meets all design considerations as per International standard EN 60051

- A shunt is therefore connected in series with the measuring unit

Benefits

- Capable of carrying high direct current

- Resistive part made of pure manganin, manganin is an alloy whose resistance value remains constant in adverse temperature conditions too

- The copper plate (connection plate) and resistive part (manganin) are brazed together, this reduces the contact losses of the shunt itself, therefore providing accurate mV drop wrt applied current.