Overview

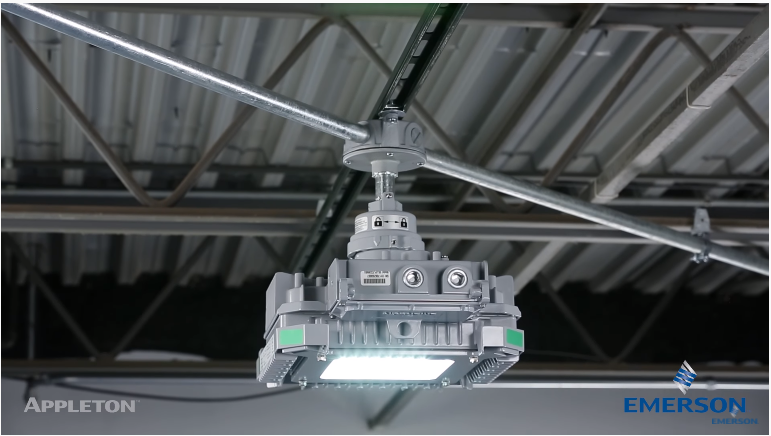

The right area lighting provides a wide distribution, uniform lighting experience for large spaces to increase safety. Street lights illuminate roadways, parking lots, sidewalks, and other public areas. They improve security and driving safety by enhancing vision in poor light conditions. Broad beamed, high intensity flood lights provide illumination for large areas with superior protection from the elements. These different lights are important to be monitored while testing to find out the working electrical supply ranges, consumption and harmonics generated from these lights.

Problem Statement

Six lamps are tested at a time through a single testing unit. For monitoring individual lamps each lamp is accompanied with a meter to monitor the different electrical parameters. So the number of meters is equal to the number of lamps. Thus, the system complexity is increased for each additional lamp and monitoring each lamp becomes a tedious task. Also, they want to log all the important parameters of each lamp and simultaneously want to view parameters of all the lamps while testing through a single testing unit.

Solution

Rish ML1410 measures important electrical parameters of multiple loads simultaneously in a single unit, eliminating the need and cost of multiple panel meters. The combination of ML1410 along with Quick fix Module for conventional CT can be employed for six or twelve individual single phase lamps. Along with ML 1410 Lumel Datalogger SM61IoT is used to log and to communicate the different multiple ML 14xx with the system via ethernet or server.

Below table represents the list of products along with the purpose they serve the application:

From the below layout diagram , we can see that a single phase supply is available which is supplied from the test unit. Multiload lamps connected in parallel with the supply unit. Rish ML1410 takes input from individual lamps through the respective CT connected at each lamp.

A common voltage supply is given to the multiload monitor. The CT measures the load current of each lamp and sends the output current of 5A to the Quick Fix module. The Module RJ05 will convert 3x 5A current to 3phase 100mA later which is given to ML1410 with the help of RJ12 Cable. The multiload monitors are interconnected with each other via RS 485. A daisy chain connection is made between the meters. The connection is done with the SM61Iot data logger. SM61 will take all the important parameter data from the respective multiload monitor and will send it to server or PC via Ethernet. The user can view all the important data of individual lamps in a single software at a time, and also it can log the parameters of those meters for future reference and analysis purposes.

Fig. 1. Layout diagram of Multiload monitor along with SM61 logger.

Benefits

- Individual parameters of Multiple single phase lamps can be monitored simultaneously.

- Due to less complexity in wiring, chances of connection error are reduced

- Power saving (Blue impact)

- Due to less meters communication with SM61 is easy

- With user assignable register feature we are able to view only important load parameters

- Operators can easily check the status of each lamp by using a single meter for respective test bench

Features

- System transparency at a glance as all data is in PC and server

- Multi Load monitoring of 4 x 3 phase loads and 12 x 1 phase loads (Hybrid)

- Residual Current Monitoring

- Three Phase Load Health Monitoring

- Tariff Based Tripping

- Monitoring Of Individual Harmonics up to 31st

- Direct remote access via Modbus/Ethernet

- Analog Graphical Representation Of Load Current

- Larger LCD display available for better visibility over distances

Below are some other application areas for ML1410

- Sub tenant energy consumption

- Individual load management

- Residual current monitoring

- Data center metering