Overview

Demand is the one of the major things which every industry wants to control to avoid heavy penalties from the utilities board. Every industry is assigned with some sanctioned load value, which they can use max at a time. If the particular industry overshoots the sanctioned demand then it disturbs the utility supply flow and misbalance’s the demand and supply flow. Big industries like Steel, Cement, Coal, Refineries, pharmaceuticals etc, always try to keep their demand values under control with the help of some external devices. Also, this big industries tries to generate the energy at their end by the means of small thermal plants or renewable energy plants.

Problem Statement

UltraTech Cement Limited is the cement flagship company of the Aditya Birla Group. Like many industries they also have a renewable energy plant (Solar Plant 5.5 MVA) at their factory which is there to run the plant. Solar plants have negligible power generation at night. So, Cement plant has to use utility energy at night for their critical loads. The sanction demand at night is 60kVA but due to some reasons it overshoots some time and that leads to penalties which are imposed by the utility. Every month they use to get a bill with penalties. For crossing demand value of 60kVA (upto 70kVA) for a 1 minute leads them to pay the demand charges of 70kVA for a month.

Solution

For the above problem Rishabh offers RIsh DMCi. A smart Demand controller which comes with a predictive demand forecasting, demand controlling status, demand simulations and 4 different modes of demand controlling. There was an issue in controlling demand with the existing setup. The CT and PT ratio was designed for 5.5 MVA power and the night controlling demand was 60kVA which is almost 1 % of existing step up. But in DMCi we can set the contract demand as per user requirement. On the bases of CT and PT contract demand can be set from 5-120% of full-scale Power. Also, the controlling trip setting can be set from 10-100% of Contract demand. This makes controlling much easier as compared to other devices.

So, keeping Contract demand at 343kVA, and trip point value at 58.3kVA (17%). With selecting the Advance demand controlling setting for Apparent power, the user was able to set different trip points for 4 relays to control or we can say to trip the unnecessary loads to avoid the demand over shoot.

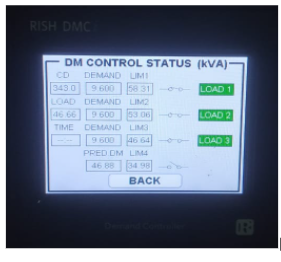

Below image shows the picture of demand control status of Plant in DMCi:

From above fig., you can observe the CD that is contract demand is 343 kVA, Current Load is 46.66 kVA. Load 1 indicates relay 1 of DMCi which is set to 58.31 kVA which is further connected to Breaker. Load 2 indicates relay 2 of DMCi which is set to 53.06kVA which is an alarm condition for indicating demand is going to shoot up in some time. All the 3 relays are going to trip on bases of current demand parameters. But Relay 4 is set on a Predictive demand parameter.

So, using all above settings and product the demand overshoot issues are resolved.

Features

- Graphical Analysis

- Time Of DAY(TOD / TOU)

- Power Quality Measurement

- Real Time Clock (RTC)

- Demand Simulations

- Custom color setting

- Predictive Demand Control