Overview

In large & closed commercial buildings such as shopping malls, hospitals, multi-storey offices etc. for effective cooling, ducts are installed. Measuring & monitoring these climatic parameters is essential. This serves in maintaining the environmental parameters circulated by the cooling duct. For this purpose, a transducer is installed for the monitoring of parameters at the required point of the cooling duct, thereby providing data related to humidity and temperature. Further actions could be initiated in order to control the room’s temperature and humidity.

Problem Statement

The major issue with the installation of the transducer was reliability of the humidity sensor. The sensor portion easily malfunctioned due to corrosive / humid / acidic environment or due to different ambient conditions at application areas. The major failure was found with the sensor part leading to incorrect data and inefficient controlling of the environment at desired thresholds.

Solution

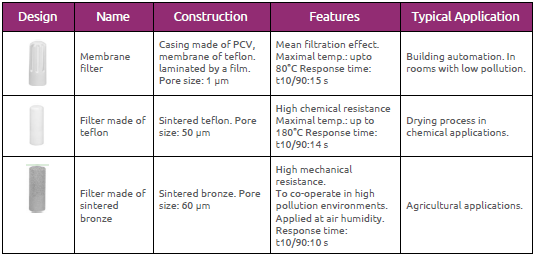

Looking at the application & area of installation, Temperature & Humidity sensor P18D was offered. The transducer included a sensor mounted on the housing with extended rod. The most important part, the sensor, was provided with a filter based on application area. The filter types are Membrane, Sintered Bronze & Teflon (Refer Table 1 for details). The one used in this particular application is of Teflon.

Cooling ducts have an opening at a specified location. The sensor tip is inserted in the same at a certain length. The filter protects the sensor from damage against the environmental factors. Every filter is built up with pores for sensors to detect the change in temperature and/ or humidity. The measurement can be locally displayed and also the information could be accessed at the centralized data monitoring system. Thus, users can take remedial action for controlling the room’s environment. The programming of the transducer is possible through the RS485 interface and marc software.

Features

- Built-in temperature and humidity sensor or with probe on 0.5 m wire

- Calculation of selected physical quantities (dew-point temperature, absolute humidity)

- Conversion of measured quantities into the output signal on the base of the individual linear characteristic

- Memory of maximal and minimal value for each measured and calculated value

- Programming of the measurement averaging time

- Servicing of RS-485 interface in MODBUS protocol in the RTU mode

- Visualisation of measured value on a LCD display

Benefits

- Multiple options for installation

- Filter options for different applications

- Reduction in sensor failure

- Local & remote display provision

- Precise monitoring & control

Applications areas

- Data Centers – in server rooms

- Substation Control Rooms – for control panels

- Hospitals & Pharmaceuticals – at storage space for medicines and other apparatus

- Chemical Plant – monitoring storage conditions of chemicals

- Food & Beverage Factory – to carry out procedures in a desired environment