The Problem

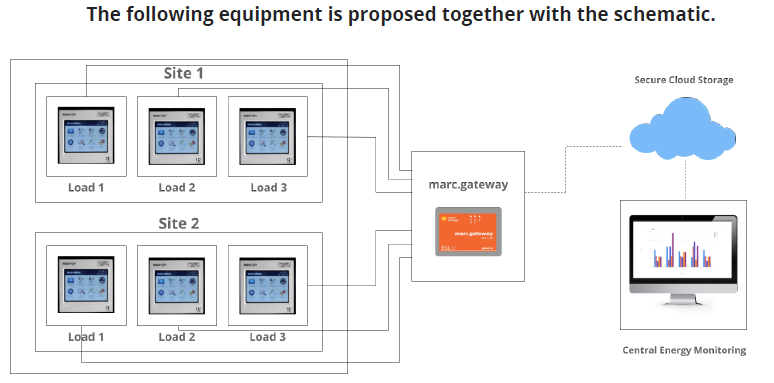

Multi-site plants/business use benchmarking as a point of reference creation for their global standards as well as creating a competitive drive in their plants. Benchmarking is the practice of a business comparing key metrics of their operations to other similar companies or their group companies.

Benchmarking of industrial equipment can lead to timely knowledge of failures or disruption in any instruments. For eg- If two sites have the similar type of equipment and instruments on site 1 requires more energy than site 2, then the instruments with site 1 has some concerns which are demanding more energy than the site 2 which can be deep dived in detail.

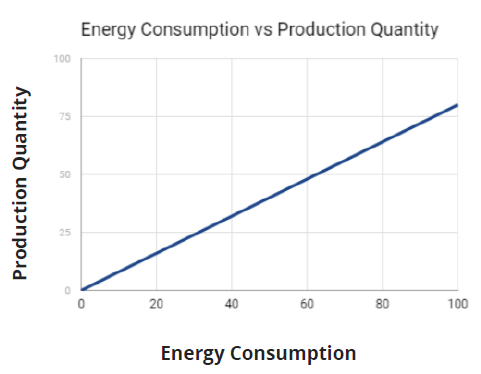

Calculated ratios of production & energy consumed can be the guiding criteria to rate plants for effective production performance management.

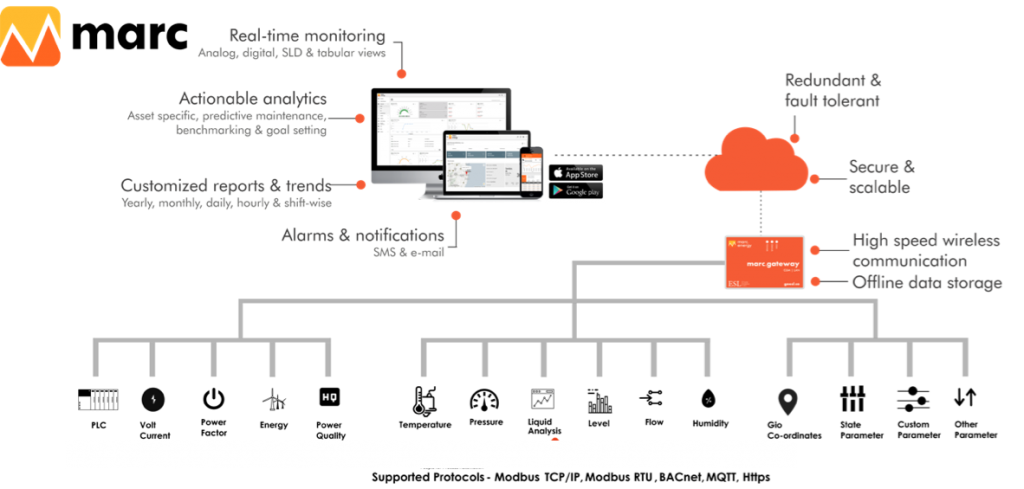

The Solution

An energy management system is an optimum solution for the benchmarking of any equipments in an industry. It does a thorough monitoring of electric energy consumption along with other parameters. Analysis of the amount and type of energy used, Current and other parameters in each system fuels analytics and a report card for each machine or equipment. These reports can prove to be of vital importance for the energy & health

benchmarking.

Along with the benchmarking, data collected in an EMS will lead to the development of a set of measures to reduce energy consumption. The EMS will provide specific information and identify real possibilities of energy savings as well as avoid critical downtime of machines. It consists of an examination of how energy is used based on accurate real time records for deriving costs and other estimates for machines.

The Benefits

- Accurate energy monitoring, real-time energy consumption

- Better information to make decisions that can help optimize energy performance

- Comparison of usage across similar facilities over time

- Early detection of maintenance issues for repair before critical equipment fails

Featured Product