The Problem

For sugar production in a sugar factory, the main process which consumes most of the electrical energy is the juice extraction and purification process. This is because purified sugarcane juice yields a far better quality of sugar. The purification process is achieved by heating the juice and treating it with chemicals like lime and sulfur to separate all impurities.

After juice purification, the seasonality of production is another factor that increases the use of energy. Due to the timing of harvest, energy consumption peaks between the months of December to February, a period that includes receiving the sugarcanes and the sugar crystals production processes. During the remainder of the year, many sugar factories have a reduced energy consumption that is associated with the storage processes. As such, the assessment and evaluation of significant production scenarios in different seasons in very crucial.

Another energy concern in sugar factory is juice crystallization process. The purified juice is evaporated to a syrup stage, bleached by sulfur dioxide and then sent to vacuum pans for further concentration and sugar grain formation. The automation of vacuum pans can be beneficial in saving electrical energy.

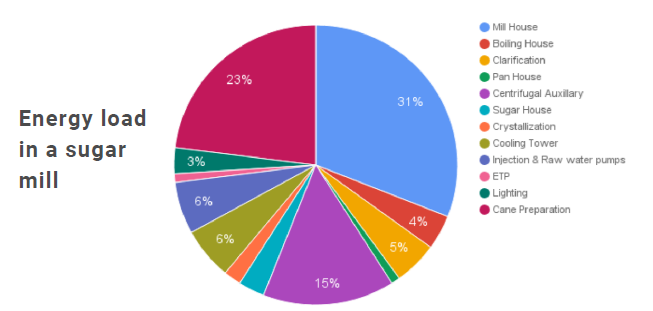

The main energy loads in a sugar factory are as follows:

The Solution

Energy management and efficiency are keys to improving productivity and quality of the sugar crystals. marc.energy is a central tool for good energy management and energy efficiency building.

An energy management system does a continuous monitoring of existing energy consumption, based on an analysis of the amount and type of energy used in each process of sugar making. Data collected in an EMS will lead to the development of a set of measures to reduce energy consumption. Thus, the EMS will provide specific information and identify real possibilities of energy savings. It does by an algorithmic examination of how energy is used based on accurate records.

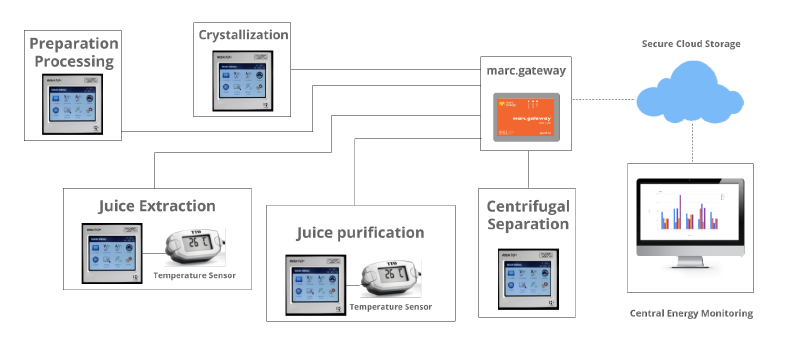

The main elements which require energy management system are:

- Juice extraction – marc.energy can store the energy data from all the grinding processes of every minute and can display it directly on the computer screen with alarms and automatic email reports.

- Juice purification – marc.energy will store all temperature data of every minute and show it directly on the computer screens.

- Crystallization – marc.energy will monitor data of pressure and humidity with regular updates and reports displayed online.

- Drying and Packaging – Storage of sugar crystals in a dry place is essential as any amount of humidity can spoil it. marc.energy will monitor data of humidity with regular updates and warn the user about through emails and/or text messages.

Schematic of the proposed solution:

The Benefits

- Accurate energy monitoring, real-time energy consumption

- Obtain correlation between energy and quality

- Granular in-depth review of facility energy data

- Better information to make decisions that can help optimize energy performance

- Ability to record actual energy usage (no estimates)

- Comparison of usage across similar facilities over time

- Ability to identify and eliminate wasted energy

- Fewer electricity shortages

- Primary fuel savings

- Reduced or deferred capital expenditures for power plant construction

- Enhanced efficiency of electric utility service

- Improving the environmental conditions

Featured products