Overview

Contact Resistance Measuring (CRM) device measures the resistance of electrical contacts of circuit breaker, isolators & busbar. It measures the resistance at the micro- or milli-ohm level and is used primarily to verify that electrical connections are proper. It helps to detect loose connections, eroded contact surfaces, contaminated or corroded contacts. It is important for contacts that carry large amounts of current as higher contact resistance leads to higher I2R losses and lower current carrying capacity.

Problem Statement

A DC contact resistance meter or a CRM is designed for accurate & reliable results while measuring the resistance of contacts. The instrument is based on the Kelvin 4-wire connection method for measurement of low resistance. Generally 100 – 200A DC test current is applied, suitable for testing contact resistance of Circuit breakers, Bus bar, Isolator & cables etc. It is very essential that the device reads the accurate value of resistance.

Calibration of these measuring instruments is important because It checks the accuracy of the instrument and includes repair of the device if it is out of calibration. When CRM devices fall out of accuracy it gives erroneous results leading to incorrect interpretation of health of contacts.

Solution

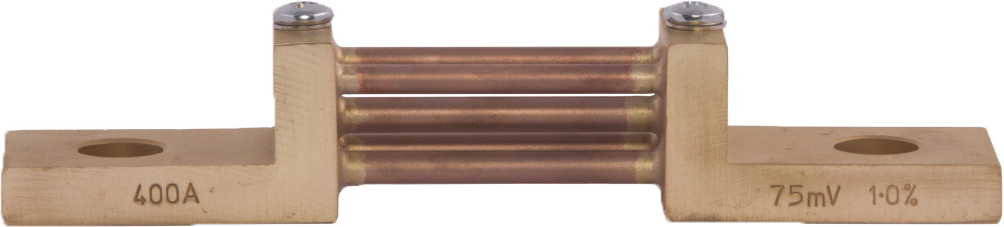

- It is essential to use a resistor or shunt which can measure currents of up to 200A and is precise so as to calibrate the instrument

- Here an external shunt is used to act as a standard calibration shunt

- Therefore Rishabh shunts are ideal for such conditions which offer an accuracy of class 0.5 as per International standard EN 60051

- A shunt is therefore connected in series with the CR measuring unit and is calibrated

Benefits

- Reliable for calibration purpose

- Resistive part made of pure manganin, manganin is an alloy whose resistance value remains constant in adverse temperature conditions too

- The copper plate (connection plate) and resistive part (manganin) are brazed together, this reduces the contact losses of the shunt itself, therefore providing accurate mV drop wrt applied current.

The following video shows the actual application of a shunt at customer premise with a Contact Resistance Measurement device :

https://drive.google.com/file/d/1r7k6LeV2hRroTZ_j5-buuRDUb_-VaZlX/view