Overview

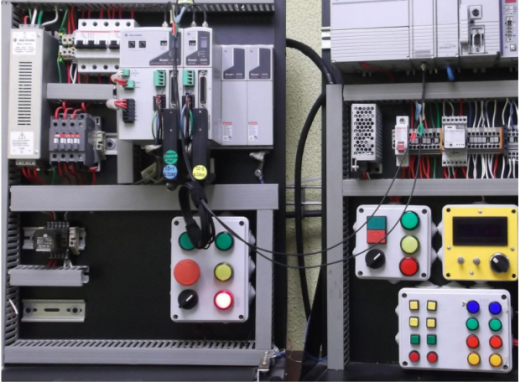

The programmable logic controllers (PLC) are omnipresent in today’s manufacturing and process industries. To achieve control operations initially, mechanical relays were used. The wiring and logic involved in utilizing mechanical relays was cumbersome, replacing them by PLC offers a simple and easy solution for modifying the operation of a control system.

The majority of PLCs used today are modular, allowing the user to include functionality in their processes using discrete control, analog control, PID control, position control, motor control, serial communication, and high-speed networking. All in all, PLCs are more reliable, easier to troubleshoot, easier to program and effective than their older counterparts.

Problem Statement

PLC is an integral component of control systems but they are equally sensitive to notorious signals and prone to failures if operated erratically. The process control loops at times behave abnormally and do not provide desired outputs. For e.g. a valve connected via output of a PLC does not open completely though the output of a PLC is 100%. Such erratic behaviour occurs due to issues either in the output current of PLC, input signal, insufficient power supply, ground current loops or loop malfunctioning.

When such irregularities occur, troubleshooting of PLC and its auxiliaries become essential.

Solution

A mA measuring clamp meter can be used as an accurate measuring device to check the operation of input/output cards on programmable logic controllers (PLCs) and distributed process control systems (DCSs). Agam’s ALCT 60A is an AC-DC Leakage clamp meter that can measure currents of magnitude 0mA~60.0A AC/DC with a resolution of 1mA AC/DC of an AC frequency response of 45Hz ~200Hz. Below steps can be followed to troubleshoot PLC

- On-field check or plant commissioning:

Starting with checking all loops of a PLC, use a leakage clamp meter to check each loop for current in a matter of seconds, without disconnecting anything. If current is not present on some loops, go on to classic troubleshooting: check the wiring, the power supply, and the control system’s I/O cards

- Troubleshooting Output cards :

For 4-20 mA input cards, feed in a known signal value (4.0 mA for zero, 12 mA for 50 percent and 20.0 mA for 100 percent) and compare it to the value shown on the meter’s readout.

The meter must read out values similar to that triggered as output on the output card. If the operator agrees with what is being sent, then there may be something wrong with the transmitter. The error can be either with the transmitter itself or, if this is a new installation, perhaps miswiring the sensor’s input to the transmitter.

In this way a quick diagnosis of PLC can be done using an AC-DC leakage clamp meter.

Benefits

- Measures leakage current accurately without the need of operators guesswork

- Reduces chances of error due to false reading

- Makes troubleshooting PLC systems easier

- Data can be recorded and used for reporting or analysis

Features

- Compact size leakage clamp meter for easy portability

- Current measurement from 1mA to 60A AC/DC

- 4-20mA DC loop current measurement without interrupting the circuit

- Data storage facility upto 99 records

- Complies with CE, CAT protection

- Software facility for online reports generation